The Prospects of Robotic Laser Welding Machines in Future Industrial Processing

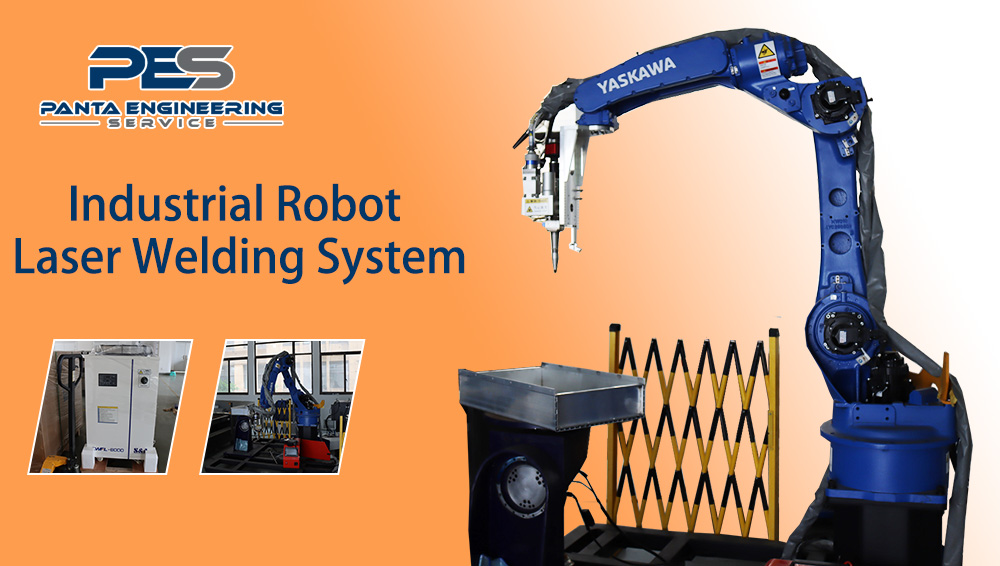

Mar 27, 2024International industrial robot application technology is becoming increasingly mature, and domestic demand is gradually increasing, which is also pushing the research and development of robot laser welding machines to a new level. The past five years have been a roller coaster ride in the industrial robot market, but now it has been applied in various Machinery equipment manufacturing, automobile manufacturing, medical equipment, aerospace, hardware tools and other industries.

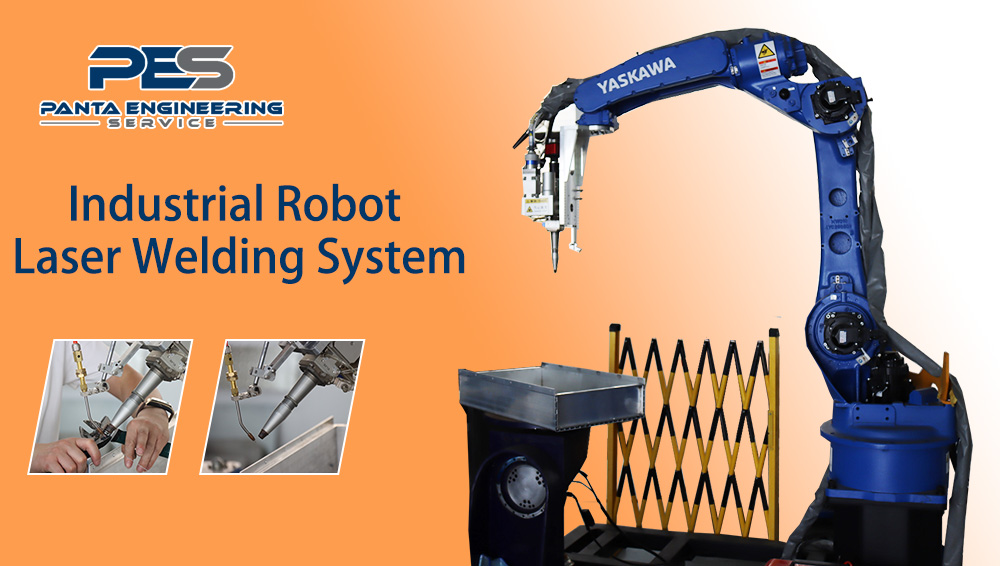

Robotic laser welding machines are easy to cooperate with computer numerical control systems or manipulators and robots to achieve automatic welding and improve production efficiency. Automated production requires reducing manpower, improving product consistency, and improving product quality. It is more suitable for mass production, reduces production costs, and improves production efficiency.

To discuss the prospects of robotic laser welding machines in future industrial processing, the first thing to understand is that according to the industry life cycle theory, the life development cycle of the industry mainly includes four development stages: infancy, growth, maturity, and decline. The characteristics of the industry in the mature stage are: the growth rate of the industry drops to a more moderate level, and the number of new enterprises will decrease; the industry entry threshold increases; and excluding the influence of technological innovation factors, the development pace of the industry is consistent with the gross national product. Stay in sync.

Robotic laser welding machines are not as common as standard welding equipment in China, but some major manufacturers are already in contact with or have used this equipment. This forward-looking attitude has also allowed the development of major manufacturers to make steady progress.

The advantages of using collaborative robots for welding processes are significantly higher than pure manual operations:

1. Human-machine collaboration eliminates the need for fences, occupies a small area, and can be quickly deployed on site to complete welding operations;

2. Simple operation, drag-and-drop teaching, easy programming, high stability and consistency, and easier control of product quality;

3. It can reduce spatter and welding slag, make welds beautiful, reduce welding difficulty and improve welding quality;

4. Programs can be saved and reused, saving manpower and material resources, and significantly reducing training costs for new employees;

5. Quickly adapt to various types of flexible welding application tasks in small batches, laying the foundation for the realization of production line automation;

6. No complicated programming is required, just teach 3 points to complete the action of drawing a circular curve (450°).

Nowadays, welding robots are increasingly used in applications, which is a major trend in the future development of the welding manufacturing industry.