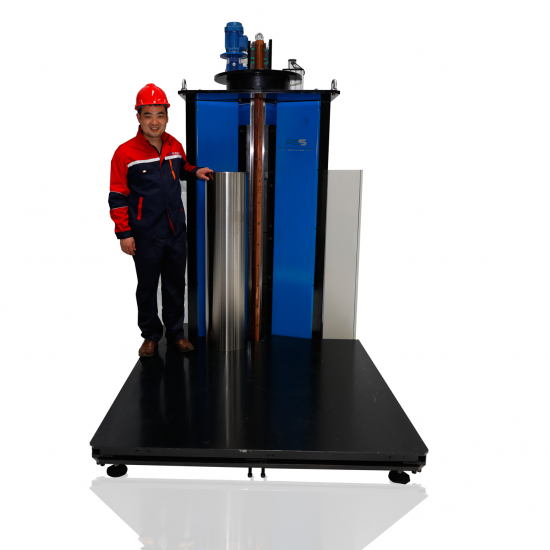

1. 올인원 조리대 디자인은 작동하기 쉽습니다.

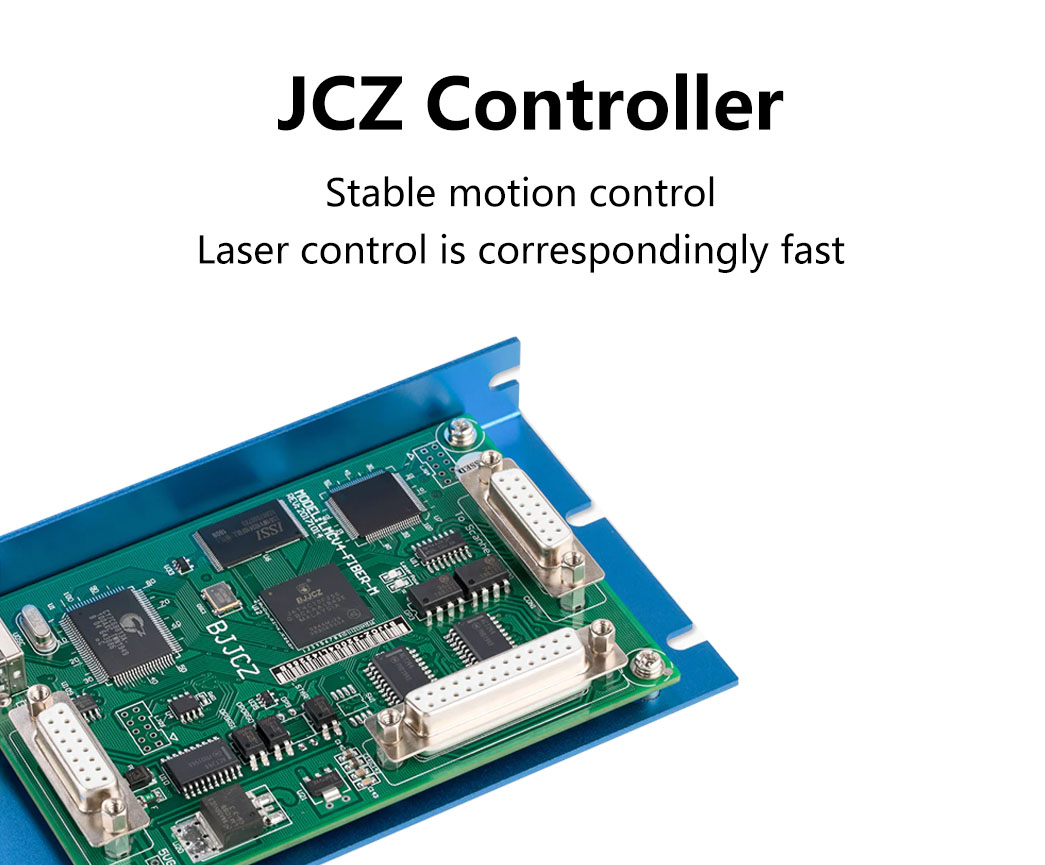

2. 고속 마킹 레이저 모션 제어 시스템 내장

3. 파이버 레이저 빔에는 좋은 품질, 높은 신뢰성 및 정밀도가 있습니다.

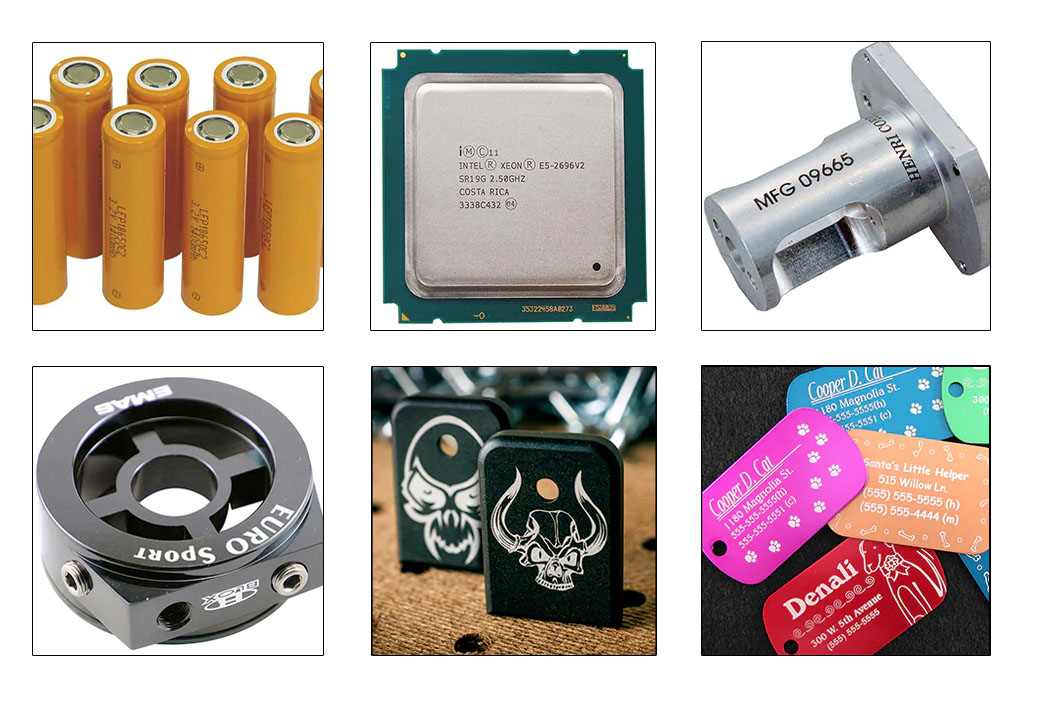

4. 금속 및 특정 비금속 재료(예: 특정 경질 플라스틱)에 대한 빠른 마킹

신청

- 은, 합금, 알루미늄, 스테인리스, 구리 등 다양한 금속에 적용 가능,

- PVC, PC, 검정 아크릴과 같은 일부 비금속 재료.

-

적용 산업:

전자, 보석, 자동차, 통신 제품, 플라스틱 버튼, IC 등에 널리 적용

IPv6 네트워크 지원

IPv6 네트워크 지원